Automatic Aerosol Filling Machines

Phoenix (DISON TEC L.L.C.) stands out as the premier online destination to buy top-quality automatic aerosol filling machines at the best prices. Having been catering to the filling needs of aerosol industry for over two decades, we have unmatched expertise in the aerosol filling technology. Our deep understanding of aerosol production allows us to design machines that meet the highest quality standards.

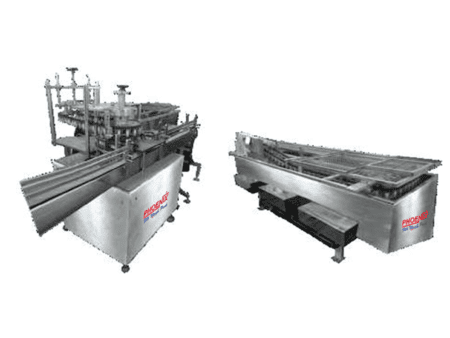

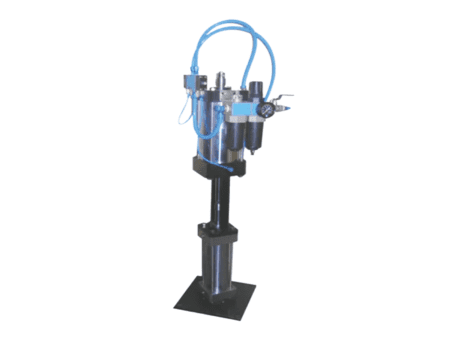

In our impressive aerosol filling line, you can find everything from an automatic valve placing and crimping machine, gassing unit, automatic pucking, to automatic capping machine, and more.

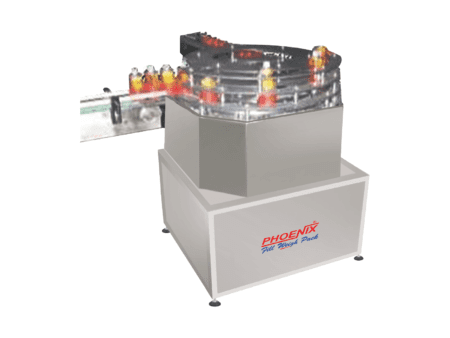

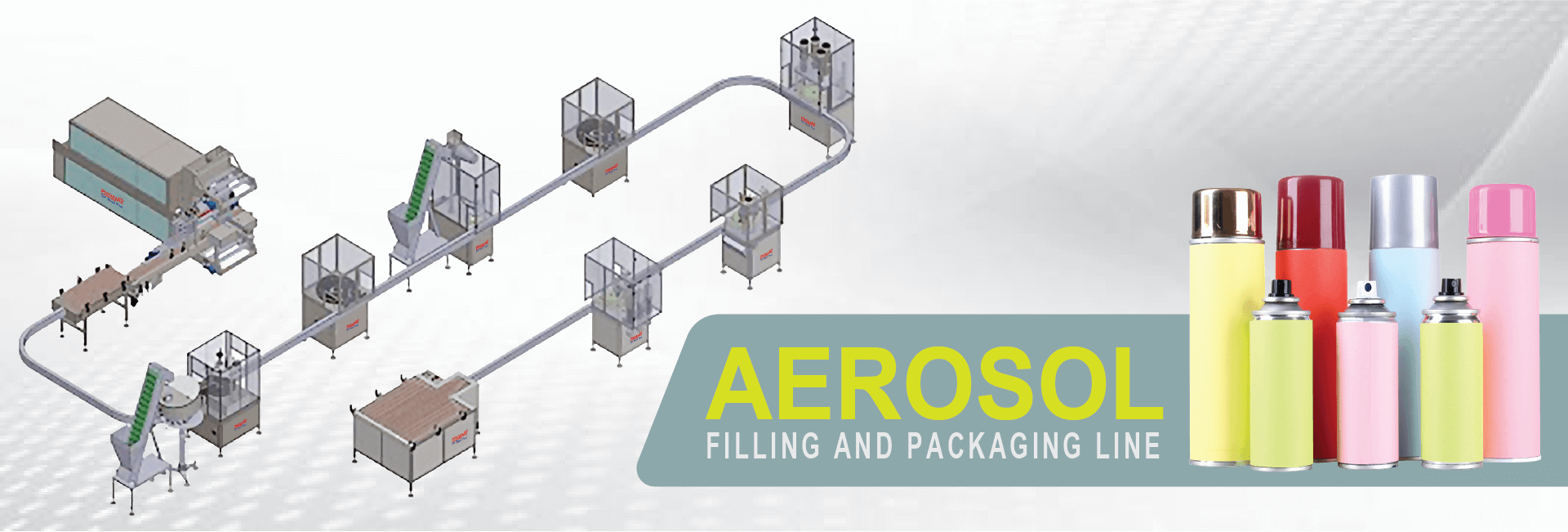

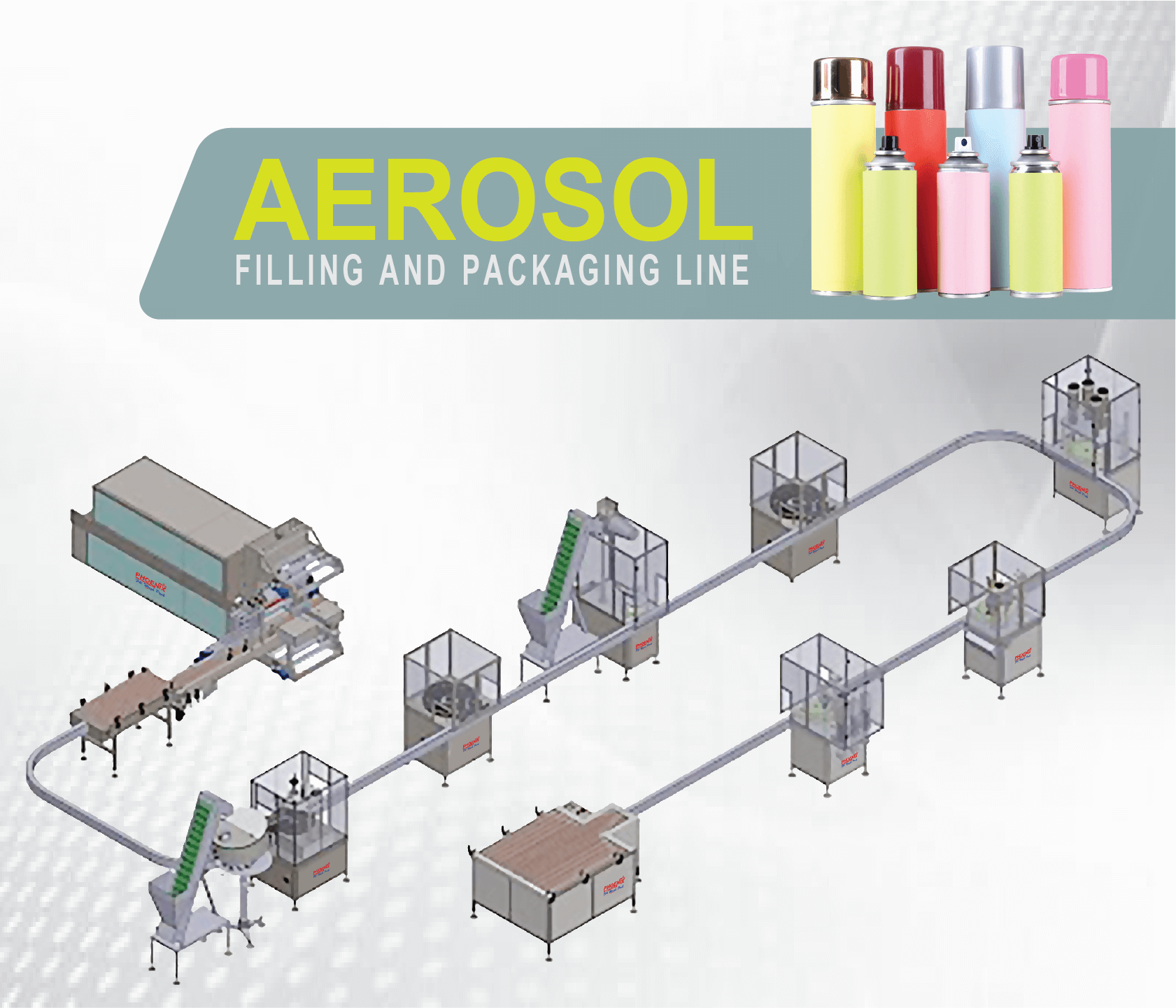

FULLY AUTOMATIC AEROSOL FILLING LINE

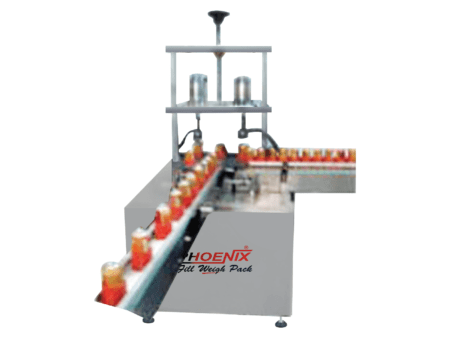

SEMI AUTOMATIC AEROSOL FILLING LINE

Advantages of Using Fully Automatic Aerosol Filling Machines

Fully automatic aerosol-filling machines offer a myriad of benefits to businesses in the aerosol manufacturing industry. Here are their key benefits –

- Improved efficiency – Fully automatic aerosol filling machines are designed for high-speed production. Their ability to quickly fill multiple aerosol cans in each cycle helps minimise downtime and maximise productivity.

- Precision and consistency – These machines ensure consistent and precise filling levels regardless of the number of aerosol cans to be filled. This helps reduce variations in the product quality.

- Reduced product waste – The precise measurement & control systems that a fully automatic aerosol filling machine is equipped with proves instrumental in reducing product waste. The reduction in waste further results in increased cost savings.

- Labour Cost Savings – The reduced need for manual labour when using a fully automatic aerosol filling machine results in significant cost savings in terms of wages as well as other labour related expenses. In addition to cutting down the operational costs, these machines also help minimise the risk of human errors.

Key Features of Semi-Automatic Aerosol Filling Machines

Semi-automatic aerosol filling machines are designed to cater to specific production requirements while maintaining some manual control. Here are some of their key features –

- User-friendly interface – Semi-automatic aerosol filling machines come with a user-friendly interface, which makes them easy to operate even for those with little to no technical expertise.

- High dosing accuracy – These machines offer a high level of dosing accuracy, ensuring each of the aerosol containers gets filled with the exact amount of product.

- Variable filling speeds – You can adjust the filling speed of a semi automatic aerosol filling machine and accommodate different product viscosities as well as container sizes.

- Cost-effective – Typically, semi-automatic filling machines have a lower initial cost than fully automatic models, making them a more cost-efficient choice particularly for small to medium sized businesses.

Choosing the Right Aerosol Filling Machine

With the increasing demand for aerosol products in Dubai, UAE, choosing the right filling machinery has to be a strategic decision for businesses that are looking to tap into this thriving market’s potential. Given below are some important factors to consider for choosing the right aerosol filling machine –

- Your production needs – Carefully evaluate your production requirements based on market demand & growth projections. Select a machine with a production capacity that you need, whether you opt for a fully automatic, semi-automatic, or manual model.

- Quality and reliability – Look for a high-quality machine that ensures product consistency throughout the manufacturing process. This will also save you from costly machine breakdowns.

- Ease of operation – Choose a filling machine with a user-friendly operation so that you can easily use it with minimal training.

- Your budget constraints – When looking for a filling machine, seek a balance between quality & cost-effectiveness while keeping in mind your budget.

- Regulatory compliance – Make sure that the aerosol filling machine you select complies with the necessary safety standards and local regulations for aerosol products in Dubai, UAE.

Ans: Automatic aerosol filling machines are known for offering a high level of precision, consistency, and efficiency in the filling process, making them an indispensable tool in industries wherein aerosol products, like deodorants, cleaning agents, and spray paints are manufactured at a large scale. Some of the industries these machines are widely used in are personal care, automotive, cosmetics, household products, and industrial sectors.

Ans: The price range for fully automatic aerosol filling machines in Dubai vary greatly depending on several factors, like the equipment’s specific features, production capacity, customization options, etc. Generally, the pricing starts from several thousand AED and goes up to tens of thousands of AED for large, high-capacity machines. For detailed pricing information about fully automatic aerosol filling machines, you can talk to our experts @ +971 6 534 9919 or +971 50 636 8423.

Ans: The production capacity of semi-automatic aerosol filling machines varies depending on the specific model and its configuration. These filling machines come in different capacities for accommodating different production requirements. The production rates generally start from several hundred cans per hour for small machines and go up to thousands of cans per hour for more advanced and larger models.

Ans: An aerosol spray filling machine is primarily used for consistent and precise filling of the aerosol cans across varied industries, like cosmetics, automotive, personal care, and many others. These machines facilitate quick and efficient filling of products, such as deodorants, body mists, spray paints, cleaning agents, and insect repellants in aerosol cans. The even distribution, consistent fill levels, and accurate dosing ensured by these filling machines help maintain product quality during the manufacturing process.