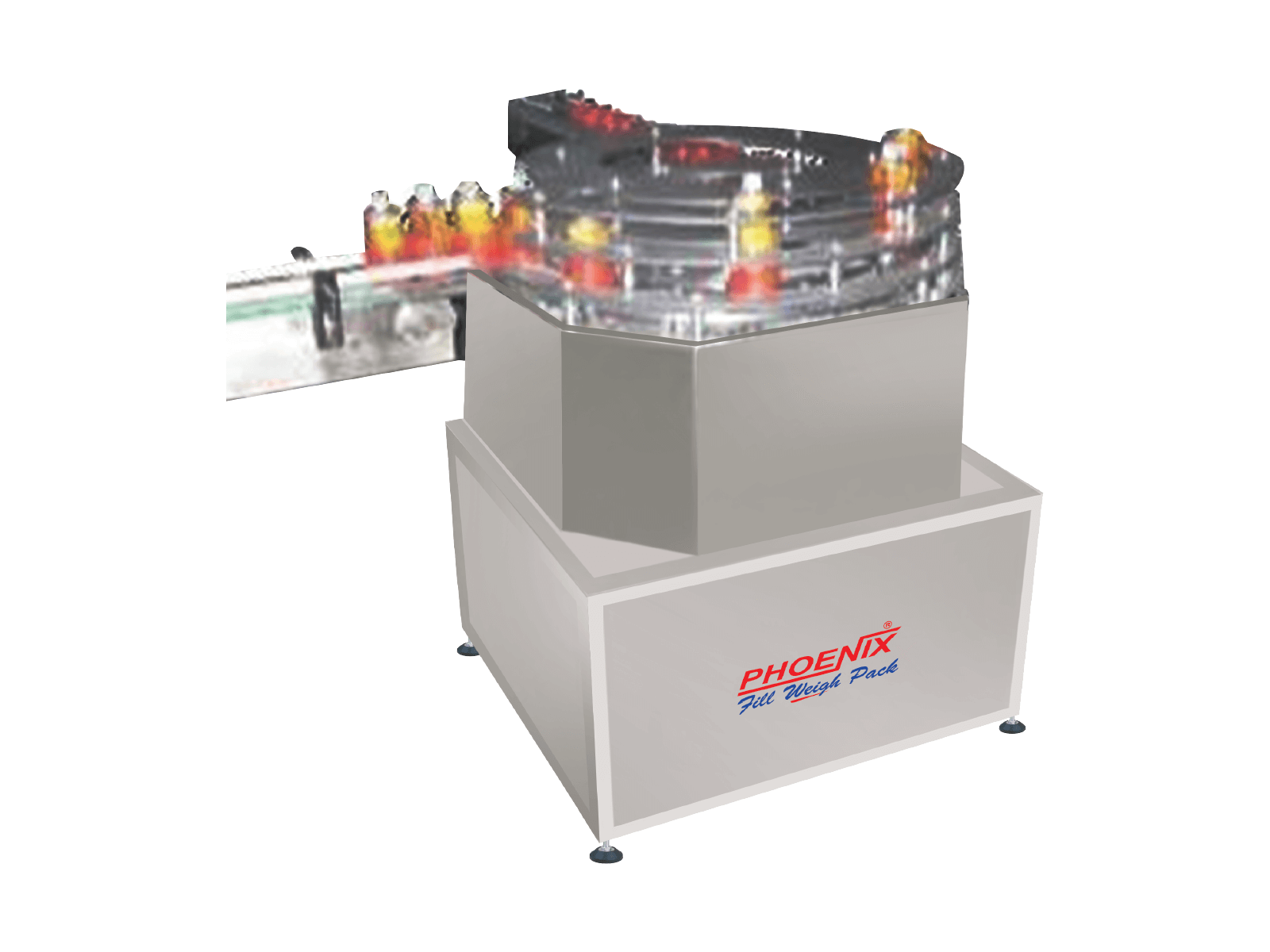

AUTOMATIC PUCKING

- Automatic Puking Cans To Pucks

- Pucking unit insert the containers into pucks automatically.

- This is a rotary unit, Cans and pucks enter to the rotary turret at different position.

- Cans are placed on to the input conveyor which transfer the cans into the turret. Pucks from output conveyor of the depucking unit enters into the pucking turret online automatically.

- Turret contains 8 pockets, also unit consist 8 shafts which is mounted exactly below all pockets and it is also moves along with pockets.

- A mechanical cam is provided at bottom and it is designed in such a way that shaft moves in up word direction gradually.

- As shaft moves it slowly starts to push the pucks from dead plate onto the cans , after travelling certain distance cans completely inserted into pucks, can with pucks are transferred into the turntable.

- Interlocks are provided so that machine starts and stops automatically.

Description

| Technical Specifications | |

| Machine Speed | 100 to 120 CPM [Depending on filling quantity] |

| Main Motor | Flame Proof Motor, 1 H.P, 6 lead, 3 phase, Foot Mounted |

| Turret | MOC: PVC, 8 Pocket |

| Number of Turrets | 2 |

| Turret Diameter | 600mm |

| Feed Height | 900mm, plus minus 50mm. |

| Overall Dimensions | 1000mm X1000mm X1750 mm height |

| Control Panel | Electrical |

| Contact Parts | SS / Alluminium /PVC |

| Non Contact Parts | MS, Hard chrome , Electroplated , Powder Coated, Spray Painted |

| Power Consumption | 1.5 K.W. |

| Product Guides | Aluminum Profile |

| Conveyor Motor | Flame Proof Motor, 0.5 H.P, 6 lead, 3 phase, Flange type |

Reviews

There are no reviews yet.